We are committed to quality, design, and innovation.

Trusted by builders and designers across Sydney.

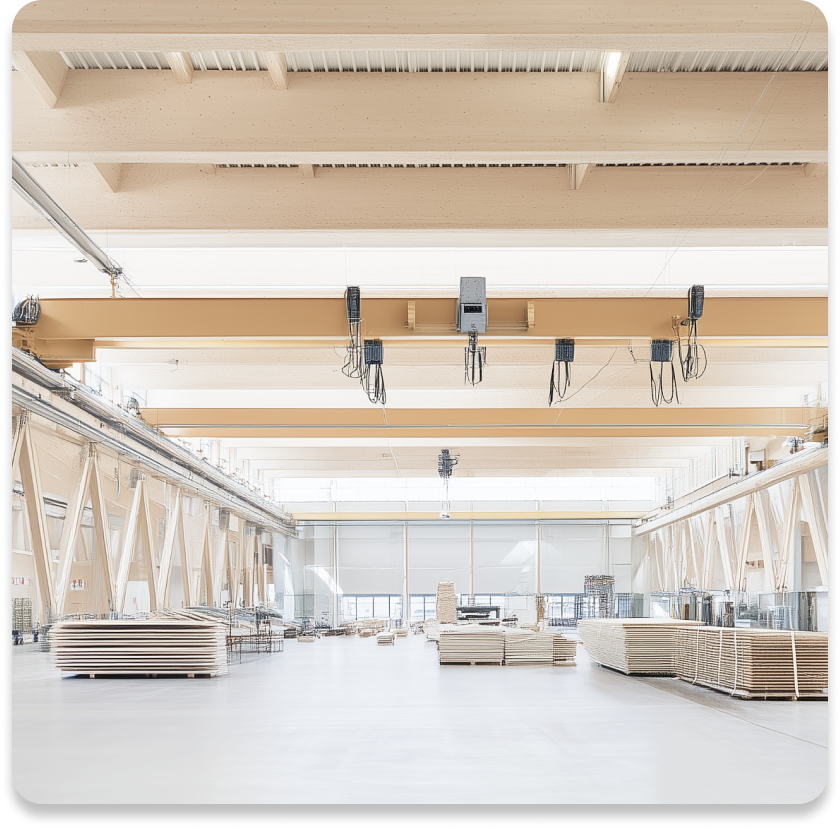

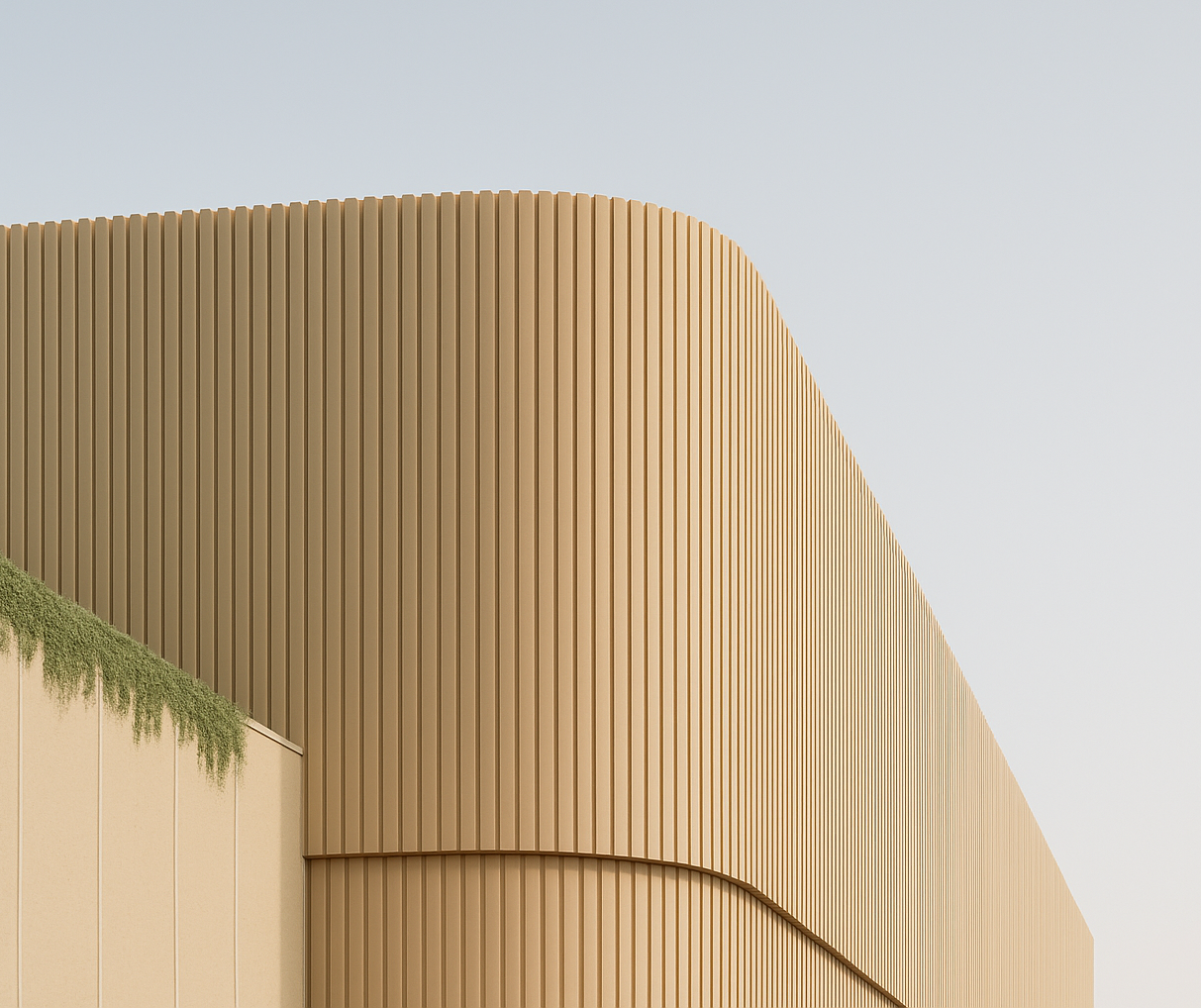

At Alpha Timber, we offer a curated range of timber, cladding, decking, and wall panels crafted for performance and style. Whether you're building from the ground up or refining the final touch, our products help bring your vision to life.

Experts Who Build With You

At Alpha Timber, our team is more than just a group of individuals we’re a collective of experts, collaborators, and problem-solvers who genuinely care about delivering the best for our clients.

With backgrounds in construction, design, and project management, our people bring a wealth of industry knowledge and hands-on experience to the table.

From offering product advice to coordinating timely deliveries, our team is committed to providing personalised support at every stage of your project. We don’t just supply materials, we become a trusted part of your process.

Delivery & Shipping

We offer fast, reliable delivery across Sydney, ensuring your materials arrive on time and in perfect condition.

Personal Account Managers

From product selection to delivery coordination, your manager is here to provide personalised support and expert advice at every stage.

Competitive Price

Our competitive pricing ensures you get exceptional value with no compromise on durability, design, or service.

Cladding samples

Not sure which cladding suits your space? We provide sample pieces so you can see the texture, colour, and finish in person.

“Our edge isn’t just in the materials we offer - it’s in how we deliver them, support our clients, and stand behind every single order.””

Who We Serve

At Alpha Timber, we proudly work with a diverse range of clients. Our product range and services are designed to meet the specific needs of:

- Builders & Contractors – Dependable supply, competitive pricing, and on-time delivery for projects of any scale.

- Architects & Designers – Premium materials with design-forward finishes to bring creative visions to life.

- Developers & Project Managers – End-to-end support and bulk supply solutions for efficient project execution.

- Homeowners & Renovators – Expert advice and beautiful product options for those creating their dream space.

Whether it’s structural timber for a build or decorative panels for a refined interior, we partner with you to deliver both quality and peace of mind every step of the way.

Discover more in our FAQ

What do I need in order to get a permit for my decking project?

What do I need in order to get a permit for my decking project?

In New South Wales (NSW), Australia, obtaining a permit for a decking project typically requires submitting an application to your local council or an accredited certifier. While the specific requirements might vary depending on your local council and the nature of your project, the following is a general list of what you may need to obtain a permit:

- Development Application (DA): For projects that don't qualify as exempt or complying development, you'll need to lodge a Development Application with your local council.

- Detailed Plans: Submit a detailed plan of the proposed deck, including dimensions, materials, and its location in relation to other structures on the property and property boundaries.

- Statement of Environmental Effects: This statement outlines the potential environmental impact of your project. For a simple decking project, this might be straightforward, but for larger or more complex projects or those in environmentally-sensitive areas, more detail may be required.

- Owner's Consent: If you're not the property owner, you'll need written consent from the owner to carry out the proposed work.

- Site Plan: This should show the location of the proposed deck in relation to property boundaries, existing structures, trees, and any other significant site features.

- Elevations: These are drawings that show the external appearance of the proposed deck, including the height and external finishes.

- BASIX Certificate: For some residential projects in NSW, a Building Sustainability Index (BASIX) assessment is required to ensure the project meets water and energy savings targets. Depending on the scope and scale of your decking project, this might be applicable.

- Application Fees: There will typically be fees associated with lodging your application. These fees can vary depending on the project and the council.

- Other Reports or Studies: Depending on the location and nature of your project, you might also need to provide additional reports or studies. For example, if you're in a bushfire-prone area, a bushfire assessment may be required. Similarly, in flood-prone or heritage areas, additional documentation might be necessary.

- Complying Development Certificate (CDC): If your project qualifies as complying development (meets specific criteria for simpler, low-impact developments), you won't need a DA but will instead apply for a Complying Development Certificate. This process is generally faster than the DA process.

Once you've gathered all the necessary documentation, you submit your application to your local council or an accredited certifier, who will then assess the application and provide a decision.

Always check with your local council or an accredited certifier for the most accurate and up-to-date requirements specific to your situation.

What type of framing material should I use for my new deck?

What type of framing material should I use for my new deck?

When it comes to building a deck, the choice of framing material is crucial because it forms the structural foundation. Several factors can influence the decision, such as budget, climate, desired longevity, maintenance commitment, and aesthetic preference. Here are the most commonly used framing materials for decks:

Pressure-Treated Lumber (PTL):

- Advantages: It's the most commonly used framing material for decks because it's relatively inexpensive and widely available. The lumber is treated to resist decay, fungus, and wood-boring bugs.

Considerations: Despite its treatment, it may still be susceptible to warping, cracking, or splitting over time. Annual inspection and regular maintenance can mitigate these issues.

1. Natural Woods (like Redwood, Cedar, and Mahogany):

- Advantages: They have a natural resistance to decay and insects without the need for chemical treatment. They also have a beautiful natural appearance and can add to the aesthetic appeal of the deck.

2. Considerations: They tend to be pricier than pressure-treated lumber. Also, the longevity can vary depending on the specific wood and its source. Like all woods, they can be susceptible to UV damage and will grey over time if not maintained.

3. Steel:

- Advantages: Steel offers immense strength, making it excellent for decks, especially larger structures or those that might support heavy loads (like hot tubs). It's also impervious to termites and won't rot.

Considerations: Steel can be expensive and might require specialized tools and expertise to work with. Additionally, while it doesn't rot, it can rust if not properly treated or if the protective coating is damaged.

4. Aluminum:

- Advantages: Like steel, aluminum is strong and resistant to rot and insects. It's also lightweight, making it easier to work with than steel.

- Considerations: It can be more expensive than traditional wood options, and the appearance might not be to everyone's liking.

5. Composite (for joists & beams):

- Advantages: Some manufacturers produce composite materials suitable for framing, not just the deck's surface. These can offer longevity and reduced maintenance.

- Considerations: Composite materials can be more expensive than traditional lumber. Also, ensure the specific composite product is rated and approved for structural framing use.

Factors to Consider When Choosing Framing Material:

- Budget: The amount you're willing to spend can significantly influence your material choice.

- Maintenance: Some materials require more maintenance than others. Decide how much time and effort you're willing to invest in upkeep.

- Climate: In areas with high humidity or frequent rain, rot-resistant materials or metals might be preferable. In areas with extreme temperature fluctuations, some materials might perform better than others.

- Aesthetics: If the framing will be visible, consider the material's appearance. Some people prefer the natural look of wood, while others might like the modern appearance of metals.

- Environmental Concerns: If sustainability is a concern, consider materials that are harvested sustainably or have a lower environmental impact.

Regardless of the material you choose, always ensure it's suitable for your intended purpose and meets any local building codes or regulations.

Do I need to place a grill mat under my grill on the deck?

Do I need to place a grill mat under my grill on the deck?

Using a grill mat under your grill when it's placed on a deck is highly recommended for several reasons:

1. Protection from Grease and Oil: Grilling can result in splatters of grease and oil. A grill mat can help prevent these from staining your deck, whether it's made of wood, composite, or any other material.

2. Fire Prevention: Embers or sparks can sometimes come out from the grill. A grill mat acts as a barrier and can help reduce the risk of these embers igniting the deck material, especially if it's made of wood.

3. Heat Protection: Grills can generate significant heat underneath them. A grill mat can help dissipate this heat and protect the decking material from potential heat damage, such as warping or discoloration.

4. Increased Safety: Spills, particularly of fatty or oily foods, can create slip hazards. By catching and containing these spills, grill mats can help maintain a safer deck environment.

5. Easier Cleanup: It's easier to clean or replace a grill mat than to clean or repair a stained or damaged deck.

6. Protect Investment: Decks can be costly to install and maintain. Using a grill mat is a relatively inexpensive way to protect your investment and keep the deck in good condition.

Selecting the Right Grill Mat:

When choosing a grill mat, consider the following:

- Size: Ensure the mat is large enough to fit under your grill with some extra space around it.

- Material: Look for mats that are heat-resistant and durable. Common materials include PVC, rubber, and certain fabric blends. Avoid mats with rubber backing on wooden decks as they can trap moisture and cause water damage.

- Thickness: A thicker mat may offer better protection against heat and dropped utensils but consider how it might affect the mobility of your grill, especially if you move it often.

- Maintenance: Check how easy it is to clean and whether it's designed for repeated use.

- Compatibility: Make sure the mat is suitable for the type of decking material you have, whether it's wood, composite, vinyl, or something else.

While it's not legally mandatory to use a grill mat on your deck, it's a good practice for the reasons mentioned above. If you're grilling on a deck, especially a wooden one, it's a small investment that can prevent damage and provide peace of mind.

What should I use for my bearing posts that support my deck?

What should I use for my bearing posts that support my deck?

The bearing posts (often referred to as support or structural posts) play a critical role in the stability and durability of your deck. Their primary purpose is to transfer the weight and load of the deck (and everything on it) to the ground or a concrete footing. Here's what you need to consider when choosing materials and methods for your bearing posts:

1. Material Choices:

- Pressure-Treated Lumber (PTL): This is the most common material used for deck posts. The wood is treated to resist decay, rot, and insect damage. Ensure the pressure-treated lumber you use is rated for ground contact if it's going directly into the ground.

- Naturally Resistant Woods: Woods such as cedar and redwood are naturally resistant to decay and insects. However, they can be more expensive than PTL.

- Steel Posts: These offer superior strength and durability, especially for elevated or large decks. They are also resistant to rot and insects.

- Composite Posts: Some manufacturers offer composite materials designed for structural use. Ensure any composite product is specifically rated and approved for load-bearing purposes.

2. Installation Methods:

- Direct Burial: The simplest method, where one end of the post is set directly into the ground. If using this method, ensure the post is treated for ground contact and consider adding gravel at the bottom of the hole for drainage.

- Concrete Footings: This is a more durable method. Dig a hole, pour concrete into it, and then either set the post directly into the wet concrete or use post anchors or brackets to secure the post to the hardened concrete footing. This method elevates the wooden post above ground, reducing the risk of decay from moisture.

- Pile Foundations: In some regions, especially where the ground freezes in the winter, deep foundations called piles are driven or bored into the ground to ensure the deck remains stable despite ground movement.

3. Considerations:

- Height of the Deck: Elevated or multi-story decks might require thicker and stronger posts due to the additional load.

- Spacing: The distance between posts will influence the deck's stability. Ensure you follow local building codes and consult structural guidelines.

- Bracing: For taller posts or in areas with high winds, cross-bracing between posts might be necessary to prevent lateral movement.

- Corrosion: If you're using metal connectors, brackets, or steel posts, ensure they are corrosion-resistant or appropriately coated, especially in coastal or wet regions.

- Local Building Codes: Always check local building codes and regulations regarding deck construction. They often specify requirements for post size, depth, spacing, and installation methods based on the deck's size, height, and load.

- Professional Consultation: Especially for larger or elevated decks, consider consulting with a structural engineer or decking professional to ensure the stability and safety of your deck.

Remember, the bearing posts are a critical component of your deck's structure. Proper material selection and installation will ensure your deck is safe and long-lasting.